The Transport Refrigeration Training studies the main tools to start in this area, the mechanical, electrical, electronic area and the tasks of the workshop are detailed.

If you understand the engineering used in transportation refrigeration systems, then you understand how all models of all brands work.

Are you interested in industrial refrigeration? Learn All About Chillers in our Chiller Training Includes Water Distribution System.

Thermo king reefer training course

Refrigerated transport enables large quantities of perishable goods to be moved and distributed from one place to another, even to distant markets, while preserving their composition and quality.

We have a training program that includes the most prestigious brands, and all types of systems present.

We have called our teaching modality “Learning by experience”, developed on the basis of online simulators.

- In each module, we present the student with an online simulator of the system to study.

- The simulator shows what function each component performs, in order for the student to understand how the entire system works.

- The student can vary the working conditions of the system within the simulator, for example amount of refrigerated product, ambient temperature, engine revolutions per minute, etc.

- By varying the working conditions, it is analyzed how a circuit responds with these changes. Faults, and symptoms can be analyzed under irregular working conditions.

- The student becomes familiar with the systems, components, and possible faults.

- The student acquires behavior experiences in each model, to apply them in real situations.

- A teacher is assigned for student questions.

- The student performs a task in each study module. Upon passing the assignment, the student advances to the next module.

Why enroll in Conforempresarial’s reefer trailer school

Because our program develops applied engineering in transport refrigeration systems. Therefore any model and brand will be included and developed here.

- A technician in charge of the maintenance of refrigerated units must be a comprehensive professional in all areas.

- In the transportation refrigeration area, it is common to change a damaged component or to perform a refrigerant recharge as corrective maintenance.

- But predictive maintenance is more important, for example, finding a fault before it affects the customer’s product, when, for example, the truck has traveled miles and cannot be attended to quickly.

- Responsiveness can be the difference between offering a good product or a broken product.

What is studied in our Transport Refrigeration courses?

Our refrigerated transport course studies in detail the equipment of the sector and its variants.

A single course that includes the operation of the systems of the main brands, in all its modalities:

- Refrigerated trucking training

- Reefer container training

- Trailers refrigeration course

Training Classes in Equipment with a compressor directly coupled to the transport motor.

Generally used in medium and small trucks, most commonly used in product distribution for short distances, or small volumetric loads.

Online training in Equipments with independent compressor to the transport motor.

Transport refrigeration models for larger trucks include a system independent from the automotive engine, with its own diesel engine.

It can be in two pieces or one, that is:

- With evaporator separated from the system.

- With evaporator attached to the equipment as a single system.

By having a compressor independent of the automotive engine, the cooling capacity is totally independent of the transport speed.

Transportation refrigeration technician training in equipment capable of working with an electrical power source while transportation is stopped.

- The refrigeration models for transport, with the possibility of diesel operation during the road, and electric with the car stopped, are ideal for product distribution over longer distances.

- The purpose of these systems is to turn on the equipment in electric mode, with the transport stopped in places where noise or work from the diesel engine is inconvenient.

Transport refrigeration school for all-electric systems.

- They have the advantage of not requiring modification to the engine part of the vehicle.

- Although it is important to mention that fully electric units often need a higher power alternator to ensure the cooling system battery charge

- These refrigeration equipment for totally electric transport have the advantage of being able to use the refrigeration system, when the car is off, using the battery for this purpose.

- Due to the use of the totally electric transport refrigeration system, zero emissions are produced from the load cooling process, allowing the use of these models at any time and in any area, even exceeding environmental regulations.

Teaching of refrigeration units for trailers

- The transport refrigeration systems for trailers are totally independent from the car engine.

- The refrigeration systems for trailers, mostly have the possibility of working with power from the electrical network, when the car is at rest.

- Refrigeration systems for trailers can have more than one evaporator, for several compartments, even at different temperatures.

- Refrigeration system for trailer with compressor coupled to the unit’s diesel engine.

- The refrigeration systems for trailers can have fans driven by bands, or with a fully electric fan system.

- Refrigeration system for trailer with electric compressor, powered by the system’s three-phase generator.

Hybrid cooling systems, a comfortable exchange between diesel and electric operating modes.

- Hybrid units for truck and trailer refrigeration automatically switch between electric and diesel operation as required or necessary.

- This allows transport companies to operate in urban centers, residential areas and low emission areas with the diesel engine of the refrigeration unit switched off.

- The driver only needs to set up the vehicle when leaving the depot and the system will seamlessly switch to electric and diesel modes during the workday, depending on the needs of the unit.

Which manufacturers of equipment for refrigeration in transport are studied in the classes of our course?

Our course offers in the same program, all the necessary learning to repair the equipment of the main manufacturers of refrigerated transport units.

- Thermo king transport refrigeration equipment

- Carrier transport refrigeration

Although Thermo king equipment is very famous, we can also find brand names that are highly recognized and with the same level of quality, such as those presented by the Carrier Transicold and Hwasung Thermo with its entire line for refrigeration in transport adaptable to all needs.

Thermo king transport Refrigeration Unit Training

We present you a Training on Thermo King transport refrigeration units based on learning all the operating strategies that the systems use,

Thermo king Training Classes

In our thermo king training classes the student learns the operation of the different models, in the mechanical, electrical and electronic part.

- During the course, the operation of the thermoking brand systems is analyzed, all with an engineering approach.

- Diagrams, control strategies, and function of each component are analyzed.

- Sensor signals and actuator activation are studied.

- The equipment is analyzed in each work mode, whether on the road or at rest.

- The technologies used in refrigerated truck and vans models are studied such as: SERIE TS, SERIE V, SERIE Ce, SERIE C, SERIE E, SERIE B, others.

- The control strategies and parts of the refrigeration cycles are analyzed, used in thermo king models for trailers such as: TK SB190, SB210, SB310, SB 110, SB300, SB 100, SB 400, SB-3 SR+, MD II MAX, THE PRECEDENT S600, others.

- The Precedent Series for thermoking trailer, presents two types of equipment: Series S. Series C.

- Among Thermo King’s single temperature refrigeration systems, the S-600, S-700 and C-600 models stand out.

- These refrigeration units are useful for transporting frozen cargo, in high temperature environments, with long distances and fuel savings.

- S Series Multi-temperature, with more than one evaporator, includes five models. The S-600M and S-610M are Precedent’s highest powered flagship models.

- The C-600M multi-temperature unit for lower power requirements.

Carrier transport refrigeration training

- This transportation refrigeration course includes models of the carrier transicold brand, with its powerful models for trucks and trailers.

- Carrier brand models are well known for the power of their compressors, and the use of very robust control systems.

- Carrier maintenance manuals are not secret, and are well known for the precision of all their procedures.

- In our learning modules, the engineering used in carrier models to refrigerate trucks is analyzed, such as: SUPRA 644 744 844, SUPRA 550-650-750-850-950, GENESIS R70/R90, X SERIES CARRIER, others.

- The Simulators include the technologies used in carrier equipment for trailer refrigeration such as: VECTOR 1800 MT, VECTOR 5100, VECTOR 6500, VECTOR 6600MT

Thermo king vs Carrier Transport Refrigeration Units

- Warning, we do not seek to convince the user of the thermoking brand that carrier is better or vice versa.

- Generally, for models of similar capacity, thermo king compressors are smaller than carrier compressors.

- Thermo king compressors are said to be more reliable than carrier compressors.

- Six-piston carrier compressors have a reputation for being able to generate a large amount of cold.

- Carrier compressors are said to work effortlessly for frozen cargo.

- The electronic components of the carrier equipment are of excellent quality.

- There are more repair shops specialized in thermo king equipment, than maintenance shops of the carrier brand.

- It is said that in extreme ambient temperatures, carrier equipment reaches and maintains the desired temperatures faster.

- Some users say that the carrier equipment is quieter than the thermo king equipment.

- The most commonly used parts such as belts and filters, are cheaper in the carrier brand, compared to thermo king parts.

- Generally, the labor for repairing thermo king equipment is more expensive compared to the labor of the carrier.

- Thermo king parts are renowned for their quality, and for being in very good condition, by meeting the recommended service hours.

- Some users claim that if the distance between the cabin and the trailer is shorter, the thermo king equipment has better performance.

- Some users claim that in the presence of low cross-air flow, thermo king equipment performs very well.

Transport Refrigeration Technician Training

Carrier and Thermoking equipment has the basic systems of a compression refrigeration equipment, that is: evaporator, compressor, condenser, expansion valve, plus variants in control systems to improve performance, or increase the useful life of the equipment.

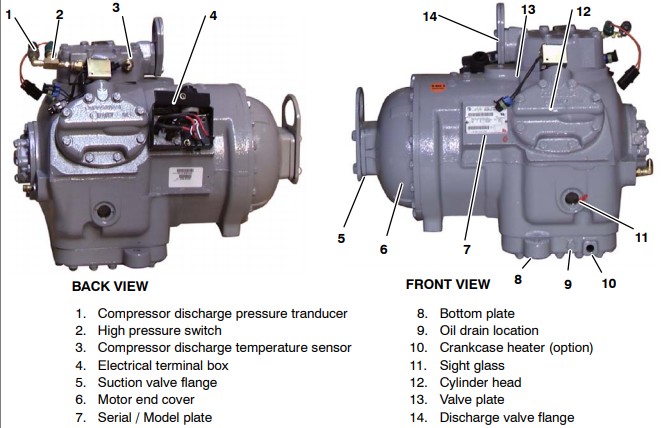

Refrigeration equipment parts in carrier and thermo king transport

Compressor:

- Produces the movement of the refrigerant within the system.

- It generates the high pressure in the system, and the low pressure in the suction.

- The type most used by thermo king and carrier is the piston compressor. The compressors can be powered by electricity, by bands or direct couplings to independent motors.

- Due to freezing temperatures, systems need high compression ratios, where the piston compressor is most efficient.

- They can have control systems, to adapt them to partial thermal loads.

- Scroll-type compressors are also used, although the favorites are piston ones.

- There are compressors always powered by electric motor, such as those used in the B-100 series for small vehicles, from the company Frascold specifically model C206

- In the compressors coupled to the vehicle’s engine, such as those used in the thermo king V series for trucks, the TM series stands out.

Expansion valves:

- In charge of delivering to the evaporator only the liquid refrigerant that the system needs.

- The thermostatic expansion valve has a bulb to measure the superheat at the outlet of the evaporator.

- Electronic-type expansion valves require a pressure sensor at the compressor suction, and a thermistor at the evaporator outlet, in order to maintain a low refrigerant superheat.

Motor:

Thermo king uses various types of motors to drive the compressors that work independently of the vehicle’s engine. For example, the engine TK270, TK370, of the yanmar brand, used in the T series are used.

condensers

Large condensers with microchannel technology, to achieve the minimum pressures required for refrigerant condensation.

THERMO KING HIGH DISCHARGE PRESSURE SENSOR LOCATION

- When the equipment works with a pressure switch, it is generally the same compressor.

- When we refer to pressure sensors, they can be located in the system piping.

The 22 Basic Concepts for Beginners in Transport Refrigeration

Objectives of the Transport Refrigeration Systems Course.

- Understand the fundamentals of refrigeration.

- Apply the refrigeration cycle in transport units.

- Manage the Inspection procedures before starting with the commissioning of equipment.

- Start the refrigeration circuit of the refrigerated transport.

- Know the procedures for Verifying the operation of the equipment.

- Carry out the diagnosis of faults and their correction.

- Apply maintenance plans to refrigerated transport unit

Contents of the Training in Refrigeration Equipment in Transport Thermo King, Carrier.

- Refrigeration Fundamentals.

- Refrigeration cycle in refrigerated transport.

- Components of a refrigeration system (compressor, condenser, evaporator, thermostatic expansion valve, hoses, connections, filters and clutches).

- Types of technologies used in transportation refrigeration systems.

- Electricity and Electronics applied to Transport refrigeration equipment.

- Components of the refrigeration cycle control system for refrigerated transport units, main models, thermo king, transicold, others.

- Refrigerants and oils.

- Inspection before starting with commissioning.

- Commissioning of the refrigerated transport refrigeration circuit.

- Equipment operation verification.

- Failure diagnosis and correction.

- Maintenance frequency.

WHO IS THE COURSE FOR?

Aimed at Participants with basic knowledge of automotive refrigeration with a desire to specialize

WHO IS GIVING THE COURSES AT CONFOREMPRESARIAL?

We work with a team of specialist engineers, with extensive field experience, consulting and training, present throughout the learning process.

IS A CERTIFICATE, DIPLOMA OR PROOF OF PARTICIPATION IS DELIVERED AT THE END OF THE COURSE?

transport refrigeration school

Physical Certificate, Signed and Sealed by Evaluating Engineer, includes the programmatic content developed in the course taking reference to the ISO 29990: 2010 Standard “Learning Services for On-Site and On-Line Training”

HOW LONG DOES THE COURSE LAST?

Virtual On Line Mode: 6 Months on average depends on the performance of the participant, with a guide tutor from the first day.

WHEN DOES THE COURSE BEGIN?

Virtual Course Immediate Start, virtual platform with 24 hours of availability, flexible consulting hours in mutual agreement with your tutor.

What distinguishes this Course from the others?

transport refrigeration school

- We have an accompaniment system for the participant with a Tutor guide who advises the student at all times, accompanies them, and administers their classes.

- Our Program Includes the electrical, electronic and mechanical area of the equipment, as well as a solid introduction to Electronic Air Conditioning.

Learn with the Transport Refrigeration Simulator the first concepts associated with the most basic systems.

- This equipment has a defrost system through the hot gas bypass method.

- In addition, as a compressor protection, a Suction Pressure Regulator is used, which allows the compressor to be protected against excessively high pressures when the defrosting process starts.

- The system uses 404 A refrigerant. You can very simply simulate the pressure and voltage values of some components in different circumstances such as system off, on, accelerated, not accelerated, with dirty or clean condenser, etc.

Thermo King Basic Equipment Simulator for Beginners Use in a small truck.

Take the Transport Refrigerator Beginner Simulator Test.

A Course for Refrigeration of transports with world presence.

We have Students from countries like the United States, United Kingdom, Israel, India, Australia, Canada, Germany and others.