Learn in Our CO2 Refrigeration Training the use of this refrigerant as an increasingly used alternative to meet the environmental demands of world organizations.

CO2 Refrigeration Systems Training

Our online CO2 refrigeration training program allows the student to learn all the variants of the work cycles present in these facilities.

To facilitate learning, online simulators are used that allow the student to be related to real systems.

Module One: Refrigeration cycle with subcritical CO2

Refrigeration cycle with subcritical CO2, with condensation temperatures below 30 ° C.

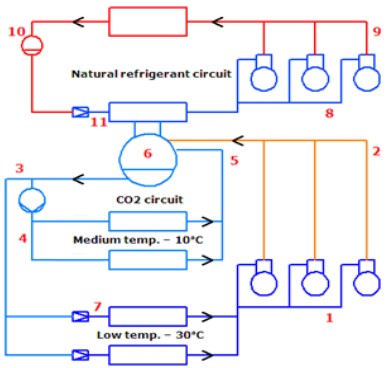

Module Two: Refrigeration with CO2 Subcritical Cascade System

In this Module the cascade systems are studied, using CO2 for low temperature, and another type of refrigerant for medium temperature.

Module three: Cascade Systems With Low, Medium Evaporators with three Refrigerants.

In these systems a third refrigerant is used, with the aim of separating the low and medium temperature systems, for which an additional glycol circuit is used.

Module four: Introduction to transcritical CO2 refrigeration systems

In this Module the refrigeration cycle with co2 with a condensation temperature above 30 ° C is studied. The discharge temperatures, yields, and need for intercooling of the R744 compression process are analyzed.

Module Five: Transcritical Refrigeration System with CO2 with parallel compressor to improve the discharge stage.

This Module studies a refrigeration system with transcritical CO2 with intermediate cooling, adding a compressor on high, to improve the COP of the system.

Module Six: Performance Improvements of the Refrigeration Cycle With Transcritical CO2 with Inverter Parallel Compressor.

The use of the inverter compressor in the transcritical refrigeration system allows the non-condensed CO2 to be compressed more efficiently.

Module Seven: Introduction to the Transcritical CO2 Refrigeration System with Ejector

In this module we study how the ejector in a transcritical system is used to reduce the compression ratio, the flow of CO2 refrigerant that enters the compressors.

Module Eight: Control strategies used in Transcritical Ejector Systems

In this module the control strategies to manage the systems that use ejector are studied.

CO2 Refrigeration Installations Course R744

- In our Training in R744 Refrigerant Carbonic Anhydride Systems, the characteristics that these facilities must have regarding safety, maintenance and energy efficiency are focused.

- The use of R744 is increasingly common as a replacement alternative for Hydrochlorofluorocarbon Refrigerants (HCFCs), which when released into the atmosphere deplete the ozone layer and contribute to overheating our planet.

CO2 Refrigeration Courses

- Our CO2 cooling course studies how these systems overcome the drawbacks of high discharge temperatures with intermediate cooling in the compression stage.

- These techniques also make it possible to improve the COP of the facilities and make their applicability more attractive in more and more sectors.

In Refrigeracipon with CO2 there are basically two types of processes:

- Subcritical: Condensation process of the refrigeration cycle with CO2 below 30 ° C

- Transcritical: Condensation process of the refrigeration cycle with CO2 above 30 ° C

Benefits of CO2 as a refrigerant

- Environmental care.

- They usually need smaller compressors than traditional systems.

- You need a smaller amount of refrigerant mass flow to achieve the same cooling capacity.

- CO2 has a lower cost than most refrigerants.

- Excellent thermodynamic properties.

- Excellent thermal exchange in evaporators and condensers.

- CO2 is a chemically inactive refrigerant, it is not flammable or toxic.

- CO2 for cooling can work in cascade systems.

- Excellent efficiency values with low temperature systems.

Why participate in our online CO2 refrigeration training?

- The greatest difficulty of cycle operation with R744 is due to the impossibility of condensing the refrigerant at temperatures below 86 ° F.

- This results in a powerful obstacle, considering that the ambient temperature in many areas exceed this value.

- For this reason, in this course the techniques used by the manufacturers are studied in detail to ensure that the superheated steam from the compressor can return as a liquid at low temperature to the evaporators and be able to function as an efficient refrigeration cycle and in most areas.

- Equipment marketed after 2022 with traditional refrigerants cannot be used in many countries.

- Area technicians must be upgraded to service new alternatives for cooling equipment.

Specific Objectives of Online CO2 Refrigeration Training

- Know CO2 as a cooling agent.

- Study the thermodynamic properties of CO2.

- Analyze the reasons for using CO2 in commercial and industrial refrigeration.

- Study the CO2 cascade systems.

- Interpret the efficiency values of CO2 installations.

- Recognize the working points of the facilities that work with CO2.

- Understand refrigeration cycles with R744 in subcritical and transcritical regimes.

- Apply the special pressure regulation controls in the application in the transcritical regime.

- Master in detail the considerations to take into account when implementing CO2 cooling systems in hot climates.

- Analyze the workshop procedures related to CO2 refrigeration.

CO2 Subcritical Circuit Simulator

One of the main feature of CO2 refrigeration systems is the fact that it can achieve condensation only below 30 ° C plus the high value of handle pressures.

Below we show a small simulator for subcritical regime (less than 20 °). In our course we will see the modifications to be able to use these systems at higher condensation temperatures (transcritical regime).