The Thermo King Alarm 63 indicates that the diesel engine driving the refrigeration compressor has stopped and fails to restart. The manufacturer provides the following description:

| Thermo King Alarm 63 | Red | Immediate Action Required: Diesel Engine Stopped |

|---|---|---|

| If the unit shuts down, repair it immediately. Otherwise, report the alarm at the end of the day. |

Why is Thermo King Fault Code 63 Triggered?

- Fault code 63 can have various causes and is often frustrating due to the range of issues that may trigger it.

- As a first recommendation, check if the fuel filters run out of fuel when the failure occurs and rule out blocked pipelines.

- In most cases, Thermo King Alarm 63 is caused by fuel-related issues.

How to Diagnose the Thermo King Fuel System?

Fault code 63 indicates that the engine has stopped functioning. It is sometimes referred to as engine lockout.

Common Causes of Engine Lockout:

- A common cause is overheating.

- Excessive heat in the exhaust system, engine, or ambient temperature can vaporize fuel in the lines, causing the engine to stop.

- To address this issue, let the engine cool down:

- Park the vehicle in the shade.

- Allow the engine to rest for a few minutes.

What to Do About Code 63 on the Control Panel?

- Download and inspect the ServiceWatch data log.

- Review the data at the technical user level to identify the operating conditions when fault code 63 was triggered.

- Use the service test mode to replicate operating conditions as needed.

- View operational data in technical mode.

- Conduct a pre-trigger test to identify the cause of the stoppage.

- Check for additional alarm codes and address each one as indicated.

How to Physically Resolve Code 63?

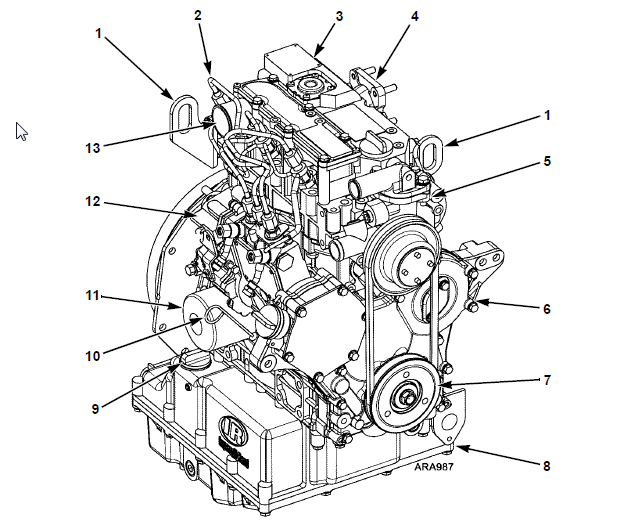

- Check the fuel level and ensure the fuel pump is functioning correctly.

- Inspect the air filter and intake hose to rule out obstructions.

Procedure to Fix Error 63

- Fuel System:

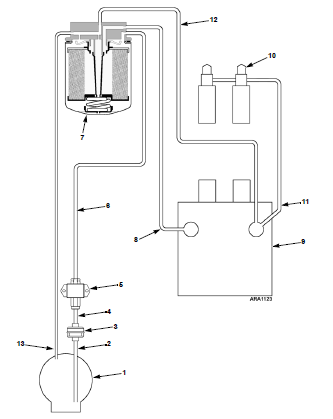

- The electric fuel pump creates a vacuum in the supply line from the fuel tank.

- Fuel passes through the filter and reaches the mechanical injection pump, which distributes it to the injectors according to the engine’s sequence.

- Fuel Level Sensor:

- Inspect the sensor, pins, and connector terminals for physical damage or corroded pins.

- Check the voltage at the harness plug (approximately 12 volts DC).

Fuel Solenoid and Alarm 63

The fuel solenoid, when energized, allows fuel to flow to the injection pump. This system also acts as a cutoff to shut down the system.

Necessary Checks:

- Verify power at the solenoid with the ignition on and the engine cranking.

- If there is no power, check fuses, relays, and solenoid wiring.

- Ensure ground connections are secure.

- Check for low battery voltage or a seized engine or compressor.